Your choice of preferred Catalyst Handling and Specialised Industrial Cleaning contractor should not be difficult. Compliance to safety, procedures & efficiency, supported by an experienced management team and world class, industry specific equipment, will ensure the success of your next catalyst turn-around.

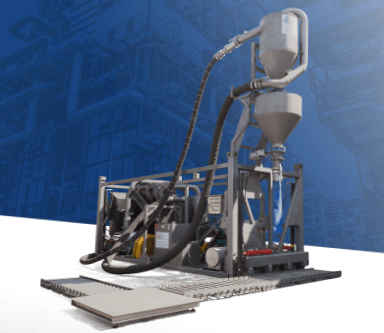

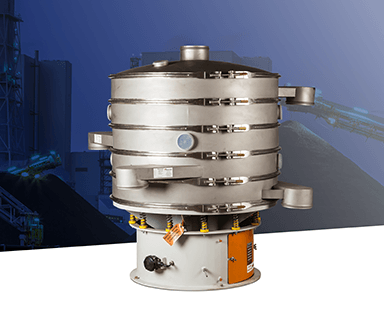

This commitment to our customers is substantiated by our continuous investment to World – Class Occupational Health, Safety, Risk and Quality management systems, ISO 9001 & ISO 45001, as well as specialised Catalyst handling equipment.

Would you like to find out more?

Our team of experts in the industry are available 24 hours a day, 365 days a years in order to assist you with your queries.